1. Umsebenzi wefomu

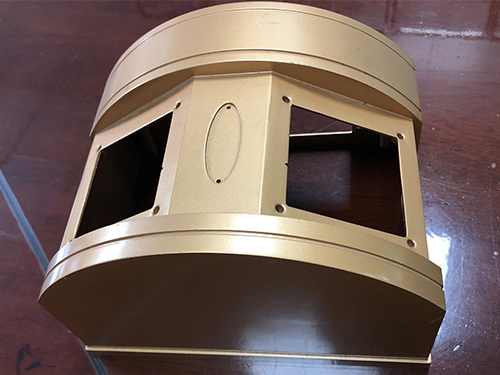

1. Indawo yangaphandle iyadingeka ukuthi igqame futhi isicaba.Izimbobo ezimbili ze-punch zengezwa kumafreyimu esikhunta angaphambili nangemuva.Naka izindawo lapho kungekho khona okokufaka ukuvimbela izingxenye ukuthi zingawi.

2. Uhlaka lwesikhunta sepuleti le-AB lufaniswa nelinye ukuze lwenze u-0.1-0.15, futhi i-baffle yamanzi endizayo iyengezwa ukuze kuvinjelwe i-aluminium ekundizeni ngaphandle futhi ilimaze abantu.

3. Ukuze uvimbele isifanekiso ukuthi singawohloki, okungenani yenza amakholomu amabili okusekela, eyodwa ku-shunt cone, kanye neyodwa kukhoni ye-shunt.Qaphela ukuthi ungaphazamisi ezinye izingxenye.

4. Isikhunta sengeza amabakaki aphakathi kuka-2-4 nabakaki abaphakathi, futhi uhlangothi lwabakaki oluphakathi lwenziwe kahle kakhulu ngomkhawulo.

5. Ipuleti eliphansi lesikhunta kufanele livuleke ukuze kube lula ukuchithwa kokushisa.

6. Amakhona amane esikhunta kufanele asikwe ukuze avimbele ekushayeni okuthunyelwe okuluhlaza ngesikhathi sokufakwa.

7. Ithebula lembobo yangaphakathi lendandatho yokumisa liyadingeka ukuthi lifakwe i-nitrided ngemva kokugaya kwangaphakathi nokupholishwa eduze kwendlela yokuphuma.

8. Ubude obusuka phansi kwendandatho yokupholisa ebusweni bendandatho yokumisa endaweni yekhoni yokuhlukanisa ngokuvamile bulingana nobukhulu bekhekhe.Kunezindlela ezimbili zokulungisa le ndandatho yokupholisa: ukushisela nokushisa nokucindezela.

9. I-shunt cone kufanele ipholiswe ngokuhambisa amanzi, futhi iqhele ngama-25-30mm ukusuka ebusweni bekhoni ye-shunt.

10. Izimbobo ezine zeziqondiso zesisekelo sesikhunta kufanele zibe yimigodi ejula ngo-8-10mm.

11. Isisekelo sesikhunta kufanele sicinywe futhi sifutheke, okungcono isisekelo sesikhunta esakhiwe.

12. Ukuze kube lula ukukhishwa kokufakwa kwesikhunta sangaphakathi, umgodi ungangezwa ebusweni besikhunta, bese kuqoqwa izikrini ezimbalwa ezingenakhanda, ukuze kube lula ukuhlakaza nokufaka esikhundleni sokufaka.

13. Izimbobo zokuphakamisa kufanele okungenani zibe ngu-M30 no-45 zijule, futhi okungenani zibe 2 phezulu.

14. Indwayimane yangaphandle kufanele ifakwe isembozo sokuvikela sasentwasahlobo ukuze kuvinjelwe isiphethu ekuwohlokeni.

15. Indawo ephakeme kunobuso besisekelo sesikhunta futhi edinga ukuthintana nomhlabathi kufanele yengezwe ngamakholomu okusekela.

2. Isikhunta sangaphakathi, faka

1. Yenza ukwelashwa kokunciphisa ukucindezeleka ngaphambi kokwelashwa ngokushisa ngemva kokucubungula.Ingxubevange ye-aluminium evamile ivala i-HRC45+/-1°C, ingxubevange ye-zinc ecisha i-HRC46+/-1-1°C

2. Ukubekezelela okufanelekile kwesikhunta sangaphakathi: Ngokuvamile, kufanele kube kuncane ngo-0.05-0.08mm kunohlaka lwesikhunta, futhi kungakhishwa kalula futhi kufakwe ohlakeni lwesikhunta ngendandatho yokuphakamisa.

Ukubekezelela ithoni lokulingana: ukuvunyelwa kwethimble okukhulu noma okulingana no-8mm kungu-0.05mm,

Igebe lethimbo elingaphansi noma elilingana no-6mm ngu-0.025mm.

3. Onke ama-engeli alungile kanye nama-acute kusikhunta sangaphakathi kufanele abe ngaphezu kuka-R0.5mm.

4. Sebenzisa izikulufu ze-flat-blade ukuvimba izimbobo ezingaphezulu kwesikhunta sangaphakathi.

3. Umgijimi kanye ne-slag discharge system design

1. Indlela yokugeleza eyinhloko yekhekhe lendwangu ku-shunt cone kufanele ibe ngaphakathi kwe-1/3 yendawo engaphezulu yombuthano.Ngale ndlela, indawo yokuhlukanisa ivaliwe ngaphambi kokuba izinto ezibandayo zingene ngokushesha emgodini.

2. Umzila oyinhloko ngaphezu kwekhoni ehlukanisiwe kufanele wenziwe umumo "W", futhi ubukhulu bekhekhe kufanele bube ngu-15-20mm.

3. Ngokuvamile, ubude bomgijimi oyinhloko kufanele bube ngu-30-35mm, futhi isikhunta kufanele sibe ngu-5-10 ° ohlangothini olulodwa.

4. Ngokuvamile, isiteshi sokugeleza kwesiphambano singcono kakhulu ukugoba futhi senze izinyathelo ezingaphezu kwezingu-2 zokuvimbela izinto ezibandayo ukuthi zingangeni emgodini ngokusebenzisa umzila wokugeleza kwesiphambano, okuholela emigqeni yokuvimbela ebandayo ebusweni bomkhiqizo.

5. Ngokuvamile, kungcono ukwengeza ama-buffers angu-2 endaweni yesango lapho isiteshi sokugeleza esiphambanweni singena khona emkhiqizweni, ukuze izinto ezibandayo zivinjelwe ngokuphelele ngaphandle komgodi.

6. Ngokuvamile, izinga le-thimble ngaphansi komgijimi oyinhloko kufanele libunjwe, futhi kufanele libe ngaphezu kuka-R2.

7. Umgogodla ophumayo ohlangothini oluphambene lomgijimi oyinhloko kufanele ugwenywe, futhi isikhwama se-slag ngakolunye uhlangothi lomgijimi oyinhloko kufanele sibe udoti kuqala, bese sivula ngokuvumelana nesimo.

8. Isikhwama se-slag singcono kakhulu ukusebenzisa indiza yenkantolo, ukuma kwe-cross-sectional semicircle, kanye ne-inlet yamanzi kanye ne-groove yokukhipha ihlukaniswe yi-1/3.I-inlet yamanzi yesikhwama se-slag kufanele futhi yeqiwe.

9. I-exhaust slot kufanele yehliswe futhi ishintshwe kahle, ngokulandela imithetho ye-"3.2.1".

10. Ukuze kube lula ukucubungula, isango ekuhlanganiseni kwesiteshi sokugeleza okuqondile kanye nomkhiqizo kufanele weqe, futhi akulula ukulahlekelwa inyama ngesikhathi sokucubungula.

4. Indlela yokudonsa eyingqikithi

1. Isilayidi kumele senziwe okungenani sibe nembobo yokufa eyodwa elengayo endaweni engaphezulu nephansi ukuze kube lula ukuhlakazeka nokuhlanganisa.

2. Phansi kwesilayidi kufanele kube umkhombe wokusika, futhi umucu ongagugi kufanele wenziwe ube yizicucu ezingu-2 ezingu-8-12mm ngaphezu kwendawo engaphansi yesikhunta ukuze kube lula ukuhlanzwa kwe-aluminium slag ngesikhathi sokukhiqiza.

3. Ubuhlalu besilayida kufanele kube umsele ongagugi, ongu-45° nendawo edonsayo.

4. Indlela yokushelela kufanele iguquguquke ekuqondiseni nasekushibilikeni, izinze ekuhambeni, ngokuvunyelwa okungu-0.08--0.12MM.

5. Ngemuva kokuthi isikhunta sivaliwe, isilayidi kanye nebhulokhi yokukhiya kufanele icindezelwe ngokuqinile, indawo yokuxhumana ayikho ngaphansi kwezingxenye ezimbili kwezintathu, futhi ine-prestress ethile.

If you'd like to speak to a member of the Anebon team for Aluminum Casting,CNC Machined Custom Service,CNC Turning Alloy, please get in touch at info@anebon.com

Isikhathi sokuthumela: Feb-25-2021