1. Kyakkyawan iyawar tsari.Lokacin da muka sami zanen zane na sarrafa sashin injin, dole ne mu hanzarta aiwatar da fasahar sarrafa wannan zane a cikin tunaninmu, tun daga kayan aiki, kayan aiki, kayan aiki, na'urorin tantance kayan aiki zuwa farashin sarrafa waɗannan matakan suna da mafi girman yanke hukunci, kuma waɗannan. hukunce-hukuncen dole ne su zama sahihan hukunce-hukunce bisa iyawar ku na ƙwararru da ƙwarewar ƙwararrun ku.Don haɓaka ingantaccen iyawar tsari, ban da ilimin fasahar sarrafa kayan aiki, har ila yau, wajibi ne a sami cikakkiyar fahimtar samfuran da aka tattara ta sassan da aka sarrafa, saboda dole ne a samar da buƙatun sarrafa wani sashi bisa ga buƙatun taro. Na wani samfur Ee, yawancin injiniyoyin ƙirar ƙirar matasa ba su da irin wannan cikakkiyar wayewar yayin yin ƙirar sashi, don haka injiniyan tsari mai kyau dole ne ba wai kawai ayyana fasahar sarrafa sashe mai ma'ana don samfurin ba, har ma yana da iyawa da wayewa don gyarawa da haɓaka samfuran. Ana amfani da rarrabuwa na injiniyan ƙira don haɓaka aikin masana'anta na samfuran daga mahimmin ƙirar tsarin sashi, amincin zaɓin kayan aiki, daidaiton juriya, da rage ƙimar masana'anta.A zahiri, wannan ita ce mafi girman darajar injiniyoyin sarrafa injiniyoyi.

2. Sanin kayan sarrafa kayan aikin bitar ku.Abin da nake nufi da saninsa yana nufin cewa dole ne ku kasance da masaniya game da iyawar sarrafawa da iyawar kayan sarrafa iri daban-daban a cikin bitar ku, da kuma irin daidaiton sarrafa kayan aikin da za su iya cimma.

1) Ƙarfin injina, wane nau'in kayan sarrafa kayan aiki ne ke da shi?Misali, juyawa, niƙa, tsarawa, niƙa, m, hakowa da sauran kayan aikin injin, wane nau'in hanyoyin sarrafa sassa ne suka dace da sarrafawa, zaku iya samun zane da sauri tabbatar da hanyoyin sarrafa wannan sashin da kuma abin da ake buƙata kayan aiki. don kammala waɗannan hanyoyin sarrafawa, sannan ku kwatanta kayan aikin da ke cikin bitar ku don yanke hukunci game da ikon sarrafawa.Wannan ƙwararren injiniyan sarrafa injin ɗin dole ne ya sami A lokaci guda, idan babu kayan aiki daidai don kammala sarrafa sashin, dole ne mu yi la'akari da ko za mu iya faɗaɗa kewayon sarrafa wasu kayan aikin ta hanyar kayan aiki na musamman ko yankan kayan aikin. .Wannan na injiniyan tsari ne mai kyau Hakanan batu ne mai ƙalubale.A yawancin lokuta, muddin ba mu yi kasa a gwiwa ba, akwai hanyoyi da yawa don magance matsalar fiye da wahala.

2) Kewayon sarrafawa, galibi yana nufin sarrafa kayan sarrafa kayan aiki a cikin bitar ku, saboda duk da yawancin nau'ikan kayan aiki iri ɗaya ne, suna da ƙayyadaddun bayanai da girma.Kewayon sarrafawa na manyan kayan aiki ya fi girma ta halitta.Lokacin da kuka samo shi Lokacin zana zane, dole ne ku hanzarta tantance ko kayan aiki a cikin bitar ku suna da ikon sarrafa su gwargwadon ma'auni na zanen.Kada mu tattauna daidaiton sarrafawa, aƙalla tabbatar da cewa bugun jini dole ne ya rufe girman sashin.A gaskiya ma, dangane da kewayon sarrafawa, har yanzu muna iya samun nasarar sarrafa wasu sassa da aka sarrafa waɗanda suka wuce bugun kayan aiki ta hanyar shigarwa ɗaya, matsewa biyu, da matsayi na tushe.Makullin shine a kasance da ƙarfin hali a cikin fasahar sarrafa sassan.Bidi'a da ci gaba.

3) Machining daidaito, dole ne ku kasance da kyakkyawar fahimta game da daidaiton sarrafa kayan aiki a cikin bitar ku, wane nau'in kayan aiki zai iya cimma wane daidaiton aiki, musamman bisa ga buƙatun zane-zane don cimma daidaiton daidaitaccen aiki, wannan. yana da mahimmanci, in ba haka ba ba za ku iya kammala yarda da abokin ciniki na ingancin injin ku ba.Idan an karkatar da daidaiton mashin ɗin kayan aikin injin, ƙwararren injiniyan injiniyan aikin injiniya na iya daidaita hanyar clamping na kayan aikin ta hanyar ka'idar karkatacciyar ka'idar daidaiton kayan aikin injin Mataki-mataki-mataki da dubawa da yawa don cimma ingantaccen aiki na sassa.Tabbas, wannan hanyar sarrafawa ita ce makoma ta ƙarshe a cikin yanayi na musamman.Don kayan aiki tare da madaidaicin sabani, har yanzu ya zama dole

Gyaran lokaci da kulawa shine sarki, amma injiniyan tsari mai kyau dole ne ya kasance mai sassauƙa kuma mai sauƙin fahimta.Za su kasance koyaushe ginshiƙan ginshiƙai da amincewar tsarin sarrafa sassa.Ma'aikatan da ke cikin bitar suna buƙatar ganinsa kawai.Idan kun ji dogaro, kun san cewa komai yana ƙarƙashin iko.

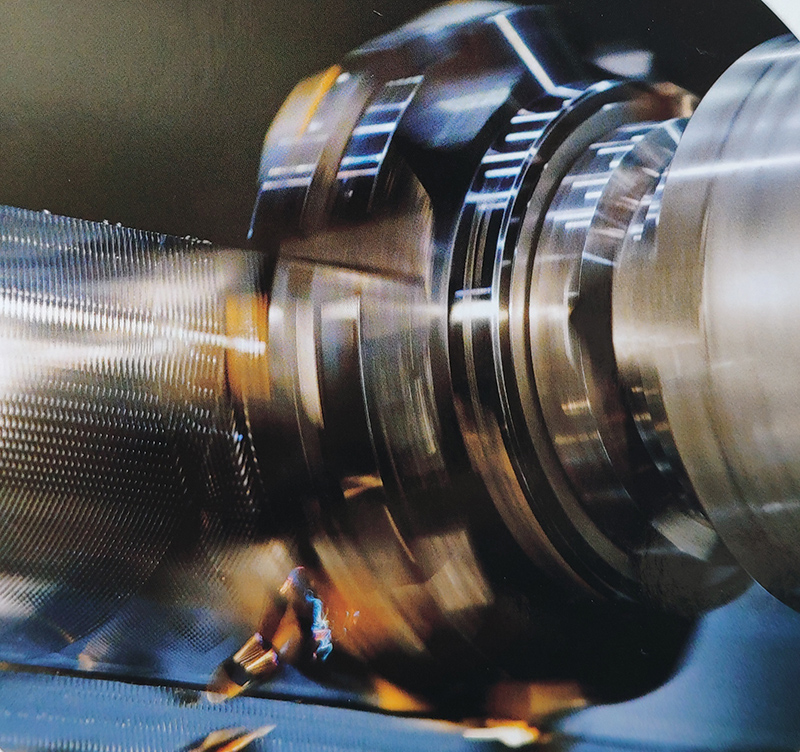

3. Kayan aikin injin, irin nau'ikan kayan aikin da ake amfani da su don sarrafa nau'ikan kayan aiki, menene saurin sarrafawa da ƙimar abinci, ko ana buƙatar sanyaya, kuma yakamata a sami hanyoyin da suka dace don mashin injin, kammalawa da kammalawa.Canjin kayan aiki da sigogin sarrafawa dole ne ba kawai tabbatar da ingancin sarrafawa da ingancin sarrafawa ba, amma kuma la'akari da farashin sarrafawa, saboda wannan koyaushe halin kasuwanci ne, kuma rashin ɗa'a ne don aiki ba tare da riba ba, kuma zaɓin kayan aikin shine. babba sosai.Ilimi, saboda yana da alaƙa da alaƙa da farashin masana'anta na sassa.Kayan aiki mai kyau ba zai iya inganta ingancin aiki ba kawai da ingantaccen aiki na sassa, amma har ma da tabbatar da kwanciyar hankali da dorewa na kayan aikin injin.A lokaci guda, zai iya tabbatar da sake zagayowar samar da sashin kuma zaɓi mai ma'ana shine ainihin ƙwarewar injiniyan tsari, kuma yana da ƙwarewar kisa na injiniyan tsari.Yawanci, ana ciyar da wannan fasaha da kuɗi, saboda kawai bayan babban gwajin kayan aiki da tarawa na sarrafawa mutum zai iya samar da kwarewarsa, da kuma tsadarsa Tsayin da tsayin zagayowar yana da ban tsoro da ban mamaki.

4. Machining kayan aiki, bisa ga siffar sassa da machining daidaito bukatun, zane-zane na gaba ɗaya ko na musamman na kayan aiki.Kwasa-kwasan tilas da ƙwarewar da ake buƙata ga kowane injiniyan sarrafa injina.Kyakkyawan daidaitawa ba kawai zai iya inganta ingantaccen aiki na sassa ba, har ma da yawa Ingantaccen daidaiton mashin ɗin na iya haɓaka kewayon sarrafa kayan aikin injin da rage farashin sarrafa sassa.Musamman tare da ci gaban kimiyya da fasaha, musamman saurin haɓakar fasahar sarrafa wutar lantarki, kayan aikin da ake amfani da su na yau da kullun na ci gaba da tafiya a hankali a cikin tsarin sarrafa kansa, tare da ƙirar huhu da na'urorin lantarki, ta hanyar amfani da na'urorin lantarki, Saitin ƙwararrun kayan sarrafa kansa ya zama daidaitaccen kayan haɗi a cikin tsarin sarrafa zamani, musamman don samfuran da aka sarrafa na zamani, kuma yawancin aikace-aikacen suna buƙatar haɓakar mai sarrafa kansa, amma kuma yana rage ƙarfi Ƙarfin aiki na ma'aikata, yana inganta yanayin aiki, da kuma inganta lafiyar aiki.A lokaci guda kuma, yana da babban garanti don ingancin sassa.

5. Gudanar da kayan aikin dubawa.A gaskiya ma, mutane da yawa suna tunanin cewa kammala sarrafa wani sashi yana nufin an kammala aikin, kuma za a iya tattara kuɗin a bar su.A gaskiya wannan kuskure ne babba.Kowane bangare da kowane tsarin aiki yana buƙatar sanye take da daidaitattun ta wannan hanyar, ana iya tabbatar da ingancin sarrafa sassan, kuma dole ne a yi cikakken ingantaccen bincike a ƙarshen.Dangane da buƙatun haƙuri da girma da siffar sassa, ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun kayan aikin ana iya aiwatar da su.Sai bayan wadannan hanyoyin za a iya cewa an kammala sarrafa kowane bangare.Tun daga fuska wajen neman kudi ga kwastomomi, a cikin tsofaffin kamfanoni mallakar gwamnati, kowane taron bita zai kasance da kayan aikin bincike mai inganci a matsayin ma'auni, kuma ma'aikatan binciken ingancin suna da matakan tantance ingancin kayan aikin.

Kayan aikin kayan aiki da hanyoyin aiki sun fi ƙwararru kuma ana amfani da daidaitattun takaddun dubawa azaman takardar shaidar wurare dabam dabam na sassan.Dole ne injiniyan injiniya mai kyau ya kasance yana da cikakkiyar fahimta da masaniya game da ƙayyadaddun ƙayyadaddun ingantattun sassan sassan, hanyoyin da dubawa, ta wannan hanyar kawai, Ta haka ne kawai za mu iya tsara fasahar sarrafa sassa da kuma samar da samfurori masu dacewa.

6. Sarrafa farashin sarrafa sassa.Duk wani sarrafa injin da ba ya ƙidaya farashi ana kiransa hooligans.Wannan dabi'a tana daidai da kashe kaji da samun kwai.Ba abu ne da talakawa za su iya yi ba.Injiniyan sarrafa injina mai kyau ba zai iya zama cikakke ba Don kammala sarrafa sassa daban-daban, yana kuma iya rage farashin gabaɗayan aikin sarrafawa, ta yadda za a iya ɗaukarsa a matsayin yin aikin injiniyan sarrafa kayan aikin.Duk wani injiniyan fasaha mai ban mamaki, mafi girman darajarsa shine sarrafa sassa Mutane da yawa suna tunanin cewa sarrafa farashi shine fahimtar ingancin sarrafa sassa.Hasali ma, a tattalin arzikin kasuwa a yau, farashi da inganci sun zama takobi mai kaifi biyu ga kamfanoni.Idan ba ku yi hankali ba, duka ruwan wukake na iya cutar da mutane.Ingancin sarrafa farashi mai ƙima shine ingancin sarrafawa mai inganci, in ba haka ba yana da gaske hooligan.

If you'd like to speak to a member of the Anebon team, please get in touch at info@anebon.com

Lokacin aikawa: Fabrairu-06-2021